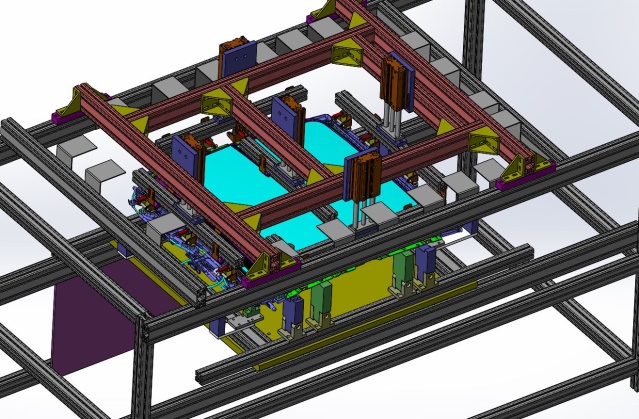

The system is a typical integration case of plant automation using for automatic production of BMW panoramic sunroof. Using robot and fast changing technology it can achieve quick changing of product. It is composed of automatic riveting station, automatic plug-in detection work station, automatic detection of noise and vibration, rolling off the production line station. Highly automated system, reduce changing time, reduces the labor intensity of workers, enhance the stability of the product, thereby improving the production efficiency and the rate of qualified products.

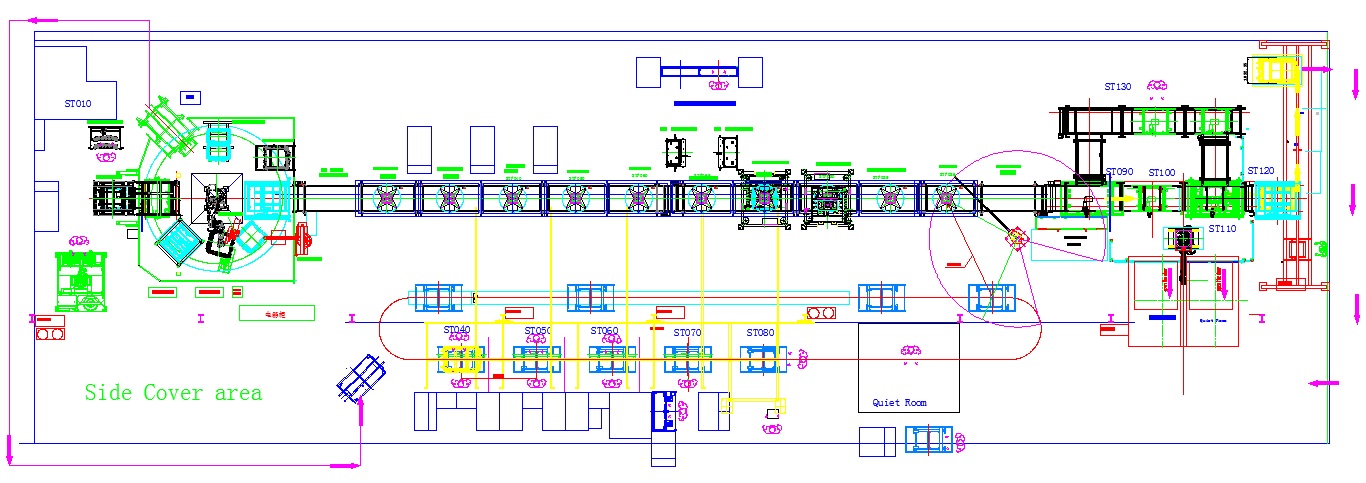

The production line of 2D layout plan

Introduction to the key station function of BMW panorama sunroof automatic production line

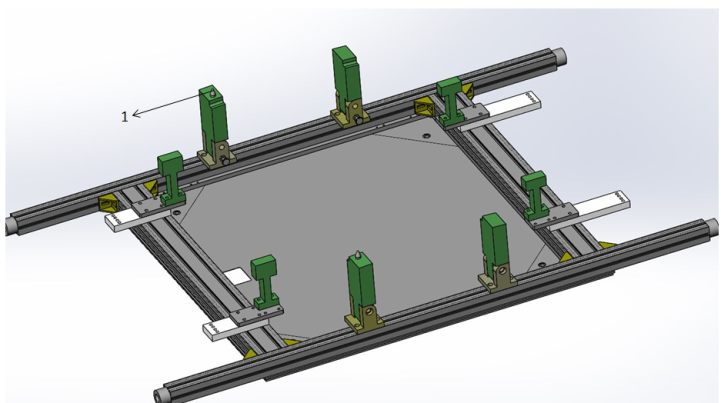

Assembly tray: loading sunroof, online cycle

1: positioning pin: sunroof rough positioning

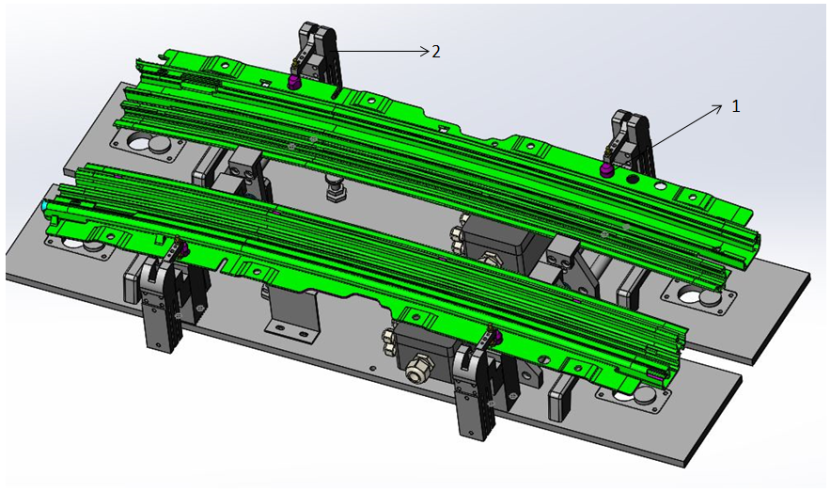

Oiling station: Rail oiling, grease coating process

1: positioning pin: positioning left and right guide rail

2: small clamping cylinder: compression Guide

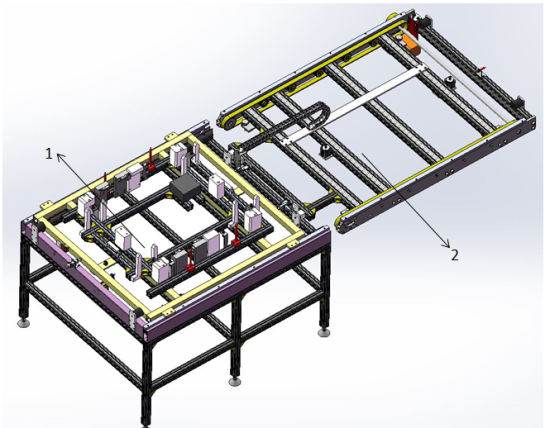

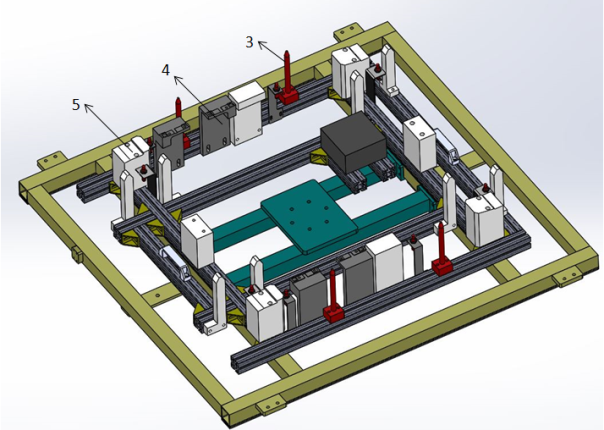

Frame pre assembly platform: sunroof frame placement and pre assembly process

5: positioning support block: front and rear beam, left and right rail support and rough positioning.

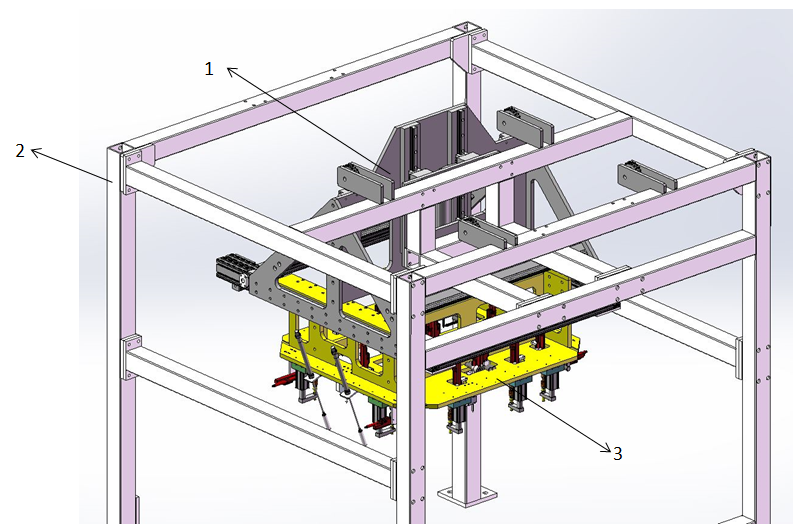

Automatic plug position: the need to automatically complete the detection station

1: cylinder: press the front beam

2: automatic plug assembly

3: positioning pin: positioning the front beam

4: motor wire harness interface (motor comes with)

5: wiring harness plug

6: cylinder: drive the plug and the motor pin contact

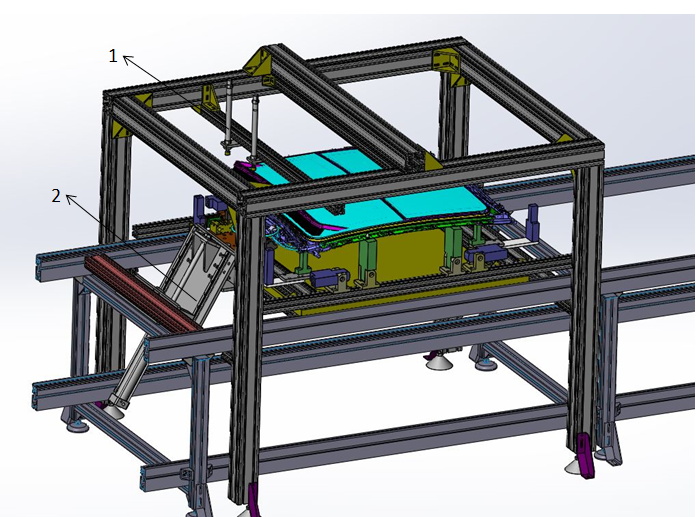

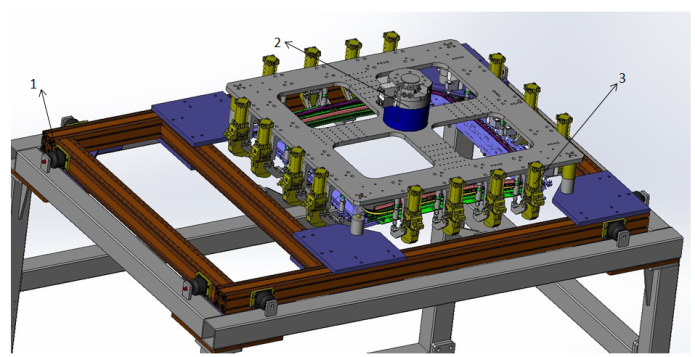

Glass height detection station: Glass height detection process

1: lifting mechanism

2: frame body

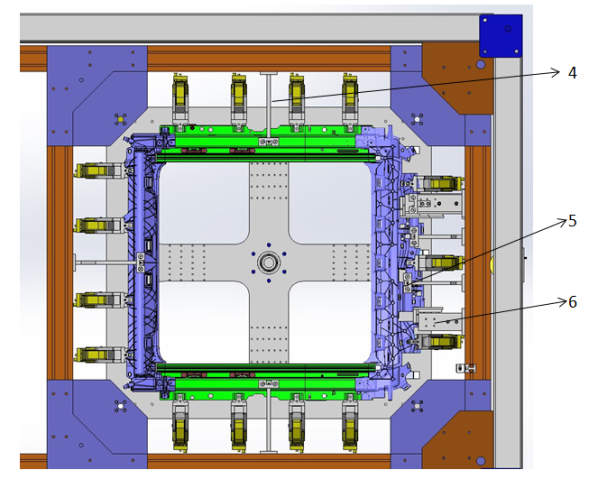

Detection station: body screws, sealing strip leak detection process

1: cylinder: control sensor lift (5 groups)

2: proximity switch: check whether the body screw leakage

3: laser sensor: after the detection of the glass seal is missing

4: laser sensor: check whether the wind screen installed

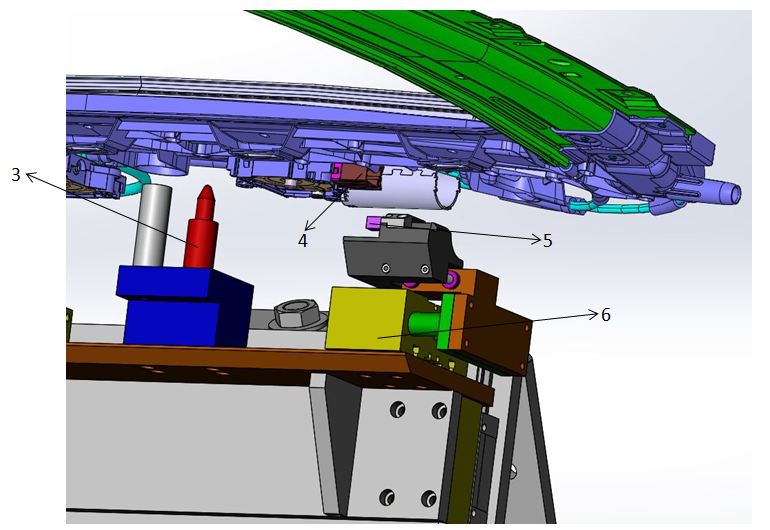

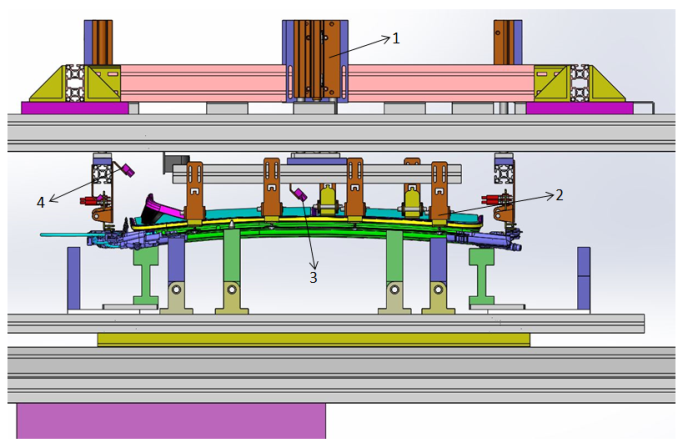

Silent room: vibration, noise detection process

1: cushion: to prevent the robot put into the hands of the tool deformation

2: quick change: function with riveting claw over grams

3: strong clamping cylinder: clamping body screw position, simulate the sunroof installed in the rear of the car (15)

4: acceleration sensor: measurement of left and right rail vibration

5: acceleration sensor: measuring motor vibration

6: automatic plug mechanism

Photos of production line

Copyright Tianjin YangTian Technology Co. LTD